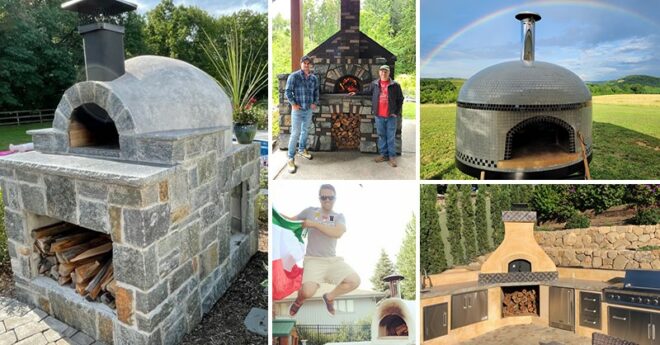

Sneak Peek of the 2021 Summer Photo Contest Entries

Jul 29, 2021With this year’s crop of 2021 Summer Photo Contest submissions rolling in, we wanted to pause and show you a few beautiful builds and fun shots that we just can’t keep to ourselves! We’ve received hundreds of photos of ovens finished in stucco, tile, and stone; mouth-watering pizzas, excited owners, and artsy “fire in the night” shots too! Preview a few of these entries below for inspiration, and then take... Read More

2020 Wood Fired Thanksgiving Recipe Contest

Sep 24, 2020Thank you for being a part of our 2020 Wood Fired Thanksgiving Recipe Contest. We can’t wait to try your delicious food and share it with the community. Our goal is to help folks assemble the most delicious, creative, and eclectic Wood Fired Thanksgiving meal ever! To submit your recipe for consideration in the contest, simply click the button below, complete the form, and upload your photo(s). Contest... Read More

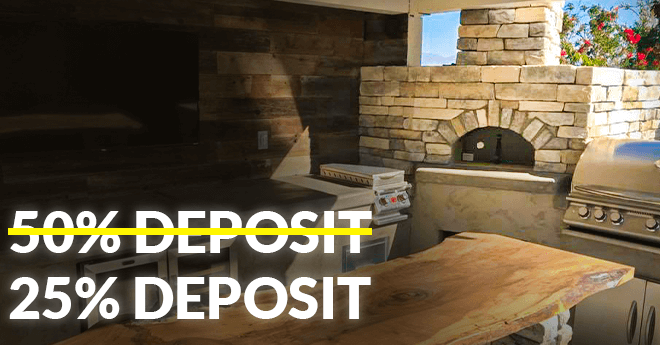

Special: Lower Deposits Make Ordering Easier

Apr 17, 2020To help make ordering (and your cash flow) easier during this time, Forno Bravo has lowered the deposit needed to order a new oven to 25%. (Down from the usual 50%.) This is a limited time offer that we are extending during the crisis as a show of solidarity with our customers and friends in the wood fired community. Benefits This discounted deposit is a win-win deal for everyone. (1)... Read More

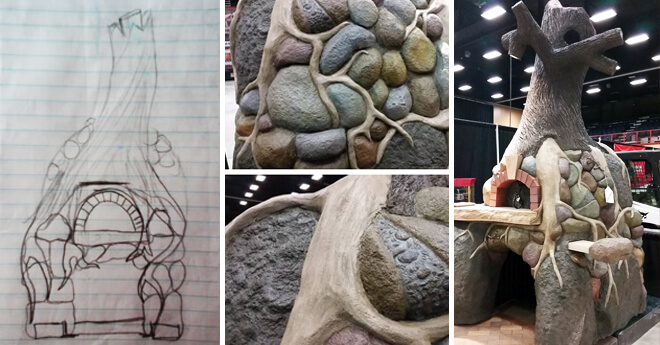

A Tree Grows in Wyoming

Jun 05, 2018What do you get when you combine a master craftsman from Wyoming and a Forno Bravo Casa2G90 Pizza Oven Kit? Magic! …and trees. Luke Bennett is with Accent Masonry, a family-owned business out of Gillette, Wyoming that has been in business 23 years. A lot of thought, planning, long hours, and an artist’s vision went into this build. He dreamed of completing a pizza oven sculptured piece that showed a... Read More

North American Pizza and Culinary Academy Opens for Classes

May 04, 2018The North American Pizza and Culinary Academy officially opened its doors on May 3, 2018. Founded by Master Instructor and world pizza champion, Chef Leo Spizzirri, and Chef Anthony Iannone, this new state-of-the-art cooking school, and test and demonstration kitchen will specialize in hands-on, interactive education for all levels and ages. The school is located just outside of Chicago in Lisle, IL. Equipment and Classes The school features several kinds of equipment, including... Read More

Forno Bravo Welcomes Guest Food Blogger, Gerry Speirs of Foodness Gracious

Apr 11, 2018Gerry Speirs of Long Beach, CA and author of Foodness Gracious is one of the newest members of our Community Cookbook, a Featured Guest Blogger, and a proud owner of a custom Napolino70 Forno Bravo wood fired pizza oven! Originally from Scotland, Gary is a blogger, photographer, cook, husband, and stay-at-home dad. His specialties are desserts and pastries, but his recipes range far and wide across the food spectrum. He... Read More

Exploring Forno Bravo Modular Kits vs Fully Assembled Ovens

Feb 14, 2018The first question a soon-to-be new pizza oven owner needs to answer is, “Am I looking for a kit or something fully assembled?” Forno Bravo Pizza Ovens run from mild to wild. Choosing the right oven isn’t about right or wrong, but about what’s right for you! This post is an exploration of our two major categories of ovens: modular kits and fully assembled ovens. We’ll be focusing on our residential... Read More

Forno Bravo and Pizza Quest Renew Partnership

Jul 27, 2016Pizza oven manufacturer promotes destination website hosted by Peter Reinhart. Salinas, CA July 27, 2016 – Forno Bravo (www.fornobravo.com) and Pizza Quest have announced a renewal of their collaboration on the pizza-themed website, www.pizzaquest.com , that began in 2010. “Pizza Quest with Peter Reinhart” is a destination website for pizza enthusiasts that contains video and blog content as well as recipes and guest columns from chefs and personalities in... Read More

A Girl and Her Dragon – She’s on Fire!

Jul 05, 2016The bright side is that, as of the writing of this latest blog, I haven’t set anything on fire that I wasn’t supposed to. I am not going to lie; there have been a few close calls. Turns out burning cornstarch will adhere to a pizza peel and turn a 6-foot cooking implement into a temporary torch. Evidently supposedly dead coals can flare up when brought out of the oven... Read More