Exploring Forno Bravo Modular Kits vs Fully Assembled Ovens

Feb 14, 2018Posted by Forno BravoThe first question a soon-to-be new pizza oven owner needs to answer is, “Am I looking for a kit or something fully assembled?”

Forno Bravo Pizza Ovens run from mild to wild. Choosing the right oven isn’t about right or wrong, but about what’s right for you! This post is an exploration of our two major categories of ovens: modular kits and fully assembled ovens. We’ll be focusing on our residential line, but many of the same considerations apply to our commercial line as well. Let’s get started.

Modular Oven Kits

Kits allow the do-it-yourselfer to save some money, express their creativity, and bring the brick oven pieces into their space without a forklift. Kits have the benefit of starting with a durable, cast refractory dome that is guaranteed to heat up quickly to very high temperatures (800°F +), hold that heat for hours, and last for years. (Starting from scratch using plans requires some extremely advanced masonry skills and lots and lots of time to achieve similar properties. Kits bypass these requirements and uncertainty.) Modular Pizza Oven Kits are still a project, but an achievable and enjoyable one for most people, with an excellent product at the end.

The Dome:

Our refractory domes are manufactured at our factory in Salinas, CA. (“Refractory” describes material that can handle very high temperatures without damage.) We engineer and control every aspect of the materials and manufacturing process for a high-quality product. The dome comes to the customer either in a monoblock style on smaller models or in interlocking pieces for the larger ones. The largest ovens also have a keystone on top to hold everything together securely. Both the monoblock and interlocking styles result in very thermally stable, durable wood and gas fired ovens.

Casa80 showing the different stages of installation

The Rest:

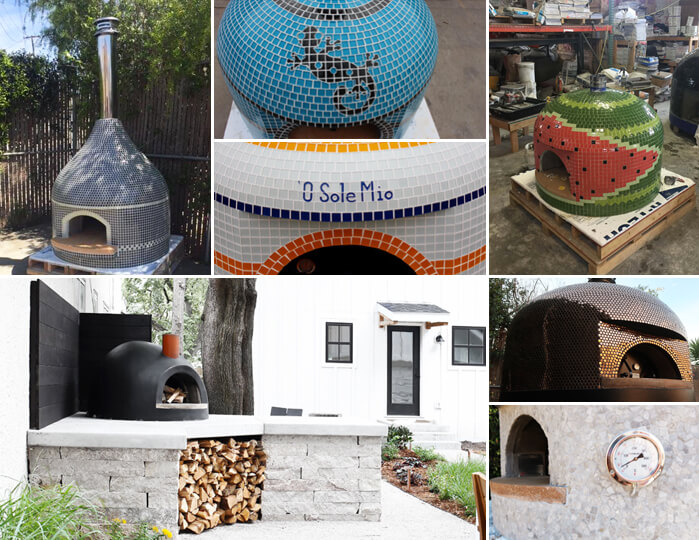

The dome is just one element. The kit also contains the rest of the components needed to successfully assemble your oven– with the cooking floor, commercial-grade insulation, and the right venting for your needs. The next steps include building your base (or using one of ours), assembling the various elements, and then custom finishing your pizza oven in whatever way you prefer. Stone, tile, concrete, brick, stucco, metal, skateboard tiles…the choices are endless and every oven is unique. Check out our image gallery and website for inspiration. Our Tech Support staff are also available to answer questions and provide encouragement before, during and after your build. Compare Modular Kits

Fully Assembled Ovens

Let’s switch over to the Fully Assembled side of the family. Kits may be easier than building from scratch, but they still require you (or your contractor) to have some building/masonry skills, and put in the elbow grease. Fully assembled ovens eliminate most of this. For the size, quality, and wide customization options, these ovens are reasonably priced for the market and the artisan product that they are!

Similarities and Differences to Kits:

Our fully assembled pizza ovens use the same refractory domes as our kits. (Yep, we are that proud of them.) The high-grade insulation is the same too. But then the process changes. Our master craftspeople take over the work of assembling and finishing the ovens for you. They are delivered complete to your home or business for installation and curing, and voila! an artisan wood or gas fired pizza oven is ready in your own indoor or outdoor kitchen. In response to customers’ requests, we’ve even added an optional curing service to help get you cooking that much faster.

The biggest challenge with fully assembled ovens, depending on the size and model you choose, is access to your backyard. These fellows are heavy! For smaller units, a pallet jack or engine hoist can be used to put them in place. For the larger pizza ovens, a forklift or larger equipment will be required. If access is limited, some customers have even used cranes to set them in the perfect spot!

Choices and Customization:

When Forno Bravo started manufacturing pizza ovens, we offered just a few models. Over the years, the line has grown into the widest variety of pizza ovens available on the market. They run the gamut of sizes, shapes, colors, and enclosures. If that’s still not enough options, with Forno Bravo, customization is king. We work with our customers around the world to create unique tile patterns, logos, colors, and finishes to fit your style and decor. Most models also come in stand or countertop models to match your kitchen’s requirements. Compare Assembled Ovens

Hints for Working with Contractors and Landscape Architects:

Pizza Ovens can be stand-alone amenities in your outdoor space, or they can be part of a full outdoor kitchen and backyard dreamscape! If you are taking it to that next level, we recommend considering working with a contractor, designer, or a landscape architect to achieve your vision. We checked in with Jim Erskine and Catherine Silver of The Arch in North Carolina. Jim is a mason with 30+ years of experience and a Forno Bravo installer. Catherine has a background in interior design. Some hints they gave for working with outside support are:

- Decide on your budget and communicate it clearly.

- Ask for references and look at samples of a contractor’s work before committing. Do get written quotes and do sign a contract to ensure that everyone is in agreement before starting the project.

- Think about your natural traffic patterns, as well as your cooking and entertaining styles. How would you like to use your oven and your space? Be realistic and tailor your design to achieve those goals.

- For wood fired cooking, consider any regular wind patterns (for drafts and smoke). Remember to account for practical logistics, like having a food prep or serving area, and waste and ash disposal locations.

- Discuss your vision with your contractor or designer, but also be open to the creativity, ideas, and experience of the professional you are hiring. Know that happy surprises may occur when working in and with natural environments.

Forno Bravo Wood Fired Pizza Oven Kits Finished and Installed by The Arch

Bella Outdoor Living Ovens

A simpler, third alternative to our kits or cast refractory ovens is our premium line of stainless steel, wood fired pizza ovens. The Bella Outdoor Living pizza ovens have the lightest weight, easiest setup, and the fastest heat-up times of any of our outdoor ovens. Heating up to 750°F+ in 15 – 30 minutes with a minimal amount of wood, they feature a Cordierite cooking floor for fast, even cooking. We manufacture these ovens and their mobile carts with 304 stainless steel in our high-tech metal factory in Colorado. The Bella pizza ovens are solid welded for strength and finished with commercial-grade, powder-coated enclosures for durability and style. While they do have some different thermal characteristics than our other ovens, they are portable, easy to assemble, and don’t require curing. They are just the ticket for many backyard chefs– true wood fired cooking with the ease of a grill.

Still need help deciding which kind of oven would be great for your home? Try our Selection Wizard or read more about our modular kits and fully assembled oven choices.