Tools

- A circular saw with three blades: general purpose wood, metal ($5) and diamond masonry ($20). The diamond masonry blade costs more, but last longer and cuts quickly.

- A hammer

- 2′-3′ level. A long level is worth is it. You can find a long, inexpensive aluminum level at Home Depot if you do not already have one.

- Grinder (optional). You can use the grinder to cut rebar, wire, and concrete block. You can buy an inexpensive grinder for about $25, which will save you time from not having to change blades on your circular saw.

- A chalk line ( <$10).

- A 1/4″ x 1/4″ notched tile trowel for the mortar base.

- Goggles and a dust mask

- A mixing tub (<$15)

- A hoe for mixing (<$10 for a cheap one, $20 for a good one. I buy the real cheap ones and toss them after the project is over).

- A square edged transfer shovel ($20).

- A tamper ($20 or build one from a square of plywood and a 2×4).

- Concrete mixer (optional). Rent one from Home Depot.

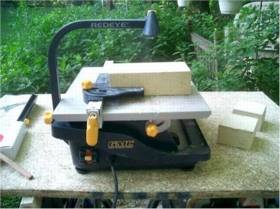

- Tile saw (optional). You can get by with a diamond blade and a circular saw. If you have complicated tile, brick or stone trim or finish, you can either rent a tile saw, or purchase a small, but functional tile saw from Home Depot for less than $100.

- Ratchetting cargo straps (optional). About $10 at WalMart. Used to hold the hearth form in place while it is curing.

Material List 42″ Oven

80″ x 94″ Foundation

- (46) 80lb bags of Ready-Mix concrete

- (8) 10′ lengths of 1/2″ rebar, (4) cut to 80″;(4) cut to 94″

- (4) 2″x6″x8′ studs for framing, (2) cut to 83″;(2) cut to 94″

- (48) sq ft of wire mesh

- (12) rebar stand-offs

- (104) sq ft of 6 mil plastic sheeting

- Handful of plastic zip-ties, or ball of tie wire

- 1/2 cu yd of gravel

- (1) box 2 1/2″ framing nails

72″ x 84 ” Block Stand

- (63) 8x8x16 blocks, (12) of which are cut to 8x8x12

- (10) 8x8x8 blocks

- (3) 10′ pieces of 1/2″ rebar, each cut into (3) 40″ sections to fill nine block cores

- (14) 80lb bags concrete for filling every other core

- (2) 1.5″x1.5″x56″ angle iron (for front span)

- (3) 60lb bag mortar (to level first course of blocks)

Insulating Hearth

- (2) 4’x’8×3/4″ sheets of plywood or particle board

- (4) 2″x4″x8′ wood studs

- (4) 2″x6″x8′ wood studs

- (1) box shims (or make your own from scrap wood)

- The rest of the 2 1/2″ framing nails

- (12) 10′ pieces of 1/2″ rebar, (6) cut to 72″; (6) cut to 84″

- (30) 80lb bags of pre-mixed concrete

- Either, (2-3) 4cu ft bags of Vermiculite or Perlite

- (2) 90lb bag of Portland Cement

- Or, (8) 12″x36’x2’ FB Board panels

Cooking Floor

- About 65 full firebricks, set on their flat side

- Fine mesh sand and fireclay

Oven Dome

- About 135 full firebricks, cut in half

- About (150-200) lbs high heat mortar

- (1) 4’x1.25″x1.25″ angle iron (cut in half)

- Styrofoam panels (for forms)

Dome Insulation

- Either, (1) 50 sq ft box of FB Blanket and (3) 4 cu ft bags Vermiculite/Perlite

- Or, (6) 4 cu ft bags of Vermiculite/Perlite

- Or, (2) 50 sq ft boxes of FB Blanket

Vent and Arch (optional)

- About (30) common clay bricks (depends on style)

- About (50) lbs. masons mortar

Chimney

- 9’ round, or 6’x10’ 24’-36’ refractory flue liner

- Or, 8’ DuraTech anchor plate, 24’-36’ chimney pipe, cap

Material List 36″ Oven

71″ x 80″ Foundation

- (30) 80lb bags of Ready-Mix concrete

- (8) 10′ lengths of 1/2″ rebar, (4) cut to 80″;(4) cut to 94″

- (4) 2″x6″x8′ studs for framing, (2) cut to 83″;(2) cut to 94″

- (48) sq ft of wire mesh

- (12) rebar stand-offs

- (104) sq ft of 6 mil plastic sheeting

- Handful of plastic zip-ties, or ball of tie wire

- 1/2 cu yd of gravel

- (1) box 2 1/2″ framing nails

63″ x 70 ” Block Stand

- (50) 8x8x16 blocks, (12) of which are cut to 8x8x12

- (5) 8x8x8 blocks

- (3) 10′ pieces of 1/2″ rebar, each cut into (3) 40″ sections to fill nine block cores

- (14) 80lb bags concrete for filling every other core

- (2) 1.5″x1.5″x56″ angle iron (for front span)

- (3) 60lb bag mortar (to level first course of blocks)

Insulating Hearth

- (2) 4’x’8×3/4″ sheets of plywood or particle board

- (4) 2″x4″x8′ wood studs

- (4) 2″x6″x8′ wood studs

- (1) box shims (or make your own from scrap wood)

- The rest of the 2 1/2″ framing nails

- (12) 10′ pieces of 1/2″ rebar, (6) cut to 72″; (6) cut to 84″

- (17) 80lb bags of pre-mixed concrete

- Either, (2) 4cu ft bags of Vermiculite or Perlite

- (1) 90lb bag of Portland Cement

- Or, (6) 12 ’x36’x2’ FB Board insulating panels

Cooking Floor

- About 60 full firebricks, set on their flat side

- Fine mesh sand and fireclay

Oven Dome

- About 120 full firebricks, cut in half

- About (130-180) lbs high heat mortar

- (1) 4’x1.25″x1.25″ angle iron (cut in half)

- Styrofoam panels (for forms)

Dome Insulation

- Either, (1) 50 sq ft box of FB Blanket and (3) 4 cu ft bags Vermiculite/Perlite

- Or, (6) 4 cu ft bags of Vermiculite/Perlite

- Or, (2) 50 sq ft boxes of FB Blanket

Vent and Arch (optional)

- About (30 or more) common clay bricks (depends on style)

- About (50) lbs. masons mortar

Chimney

- 8’ round or square, 24″-36″ refractory flue liner

- Or, 6’ DuraTech anchor plate, 24’-36’ chimney pipe, cap

Hints and Tips

Check Home Depot to locate Vermiculite and Perlite. You might find it in their garden center. If not, try pool supply (chemicals, etc.) and agriculture supply (fertilizer, etc.) stores. The large bag costs less than buying lots of small bags from a nursery.

We recommend using a dust mask when working with the loose fill. Caution. Perlite can be coated with silicone to make it slide easily into block cores, where it’s commonly used to insulate block walls. Make sure you locate plain, horticultural grade Perlite, not the construction grade. The insulating properties are nearly identical.

For your convenience, you can find high temp mortar, dome insulation, floor insulation, and multiple venting options in our online store under Installation Supplies, or links to more information about these items in our resource library and on the Product Installation Supplies page. Happy building!

Grinder, blades, goggles and dust mask.

Trowels, chalk line, and tape measure

Good, cheap tile cutter

Cutting a brick (one pass the tap with a chisel, or two passes)