Just spent some time translating this. Most of it will seem basic to most of you but hopefully someone will find some useful information.

Uruguayan and Argentinian grilling styles differ mostly on the fact that you will never see an asado being made using charcoal in Uruguay, always firewood. Of course, it's mostly a matter of tradition, except for the small amount of smokiness that can be transferred to the meat (yum).

A small note on the use of the word parrillero throughout the document: in uruguayan spanish a grill, as in cooking surface, is a parrilla. A grill, as in the whole structure that holds the cooking surface, hood, etc, is called a parrillero (not so in Argentinean spanish, where the parrillero is the cook using the grill). I couldn't find an equivalent word in english to translate it, so I kept using parrillero throughout.

Images are from a scan of the original document, which can be found in pdf form here (in spanish): parrillerofamiliar.pdf

Here it goes:

Originally published in the 1988 Almanaque Anual del Banco de Seguros del Estado (Uruguay)

By Arq. Diego C. Venturini

The delicious practice of grilling and savoring meat ?on the coals? exists within our people since yore.

Throughout time said practice has been perfected and from the old parrilla criolla laid on the ground, different improvements have been made, looking in them to achieve more comfort and efficiency.

The main objectives, when building a parrillero are:

* firewood economy

* time saving

* comfortable working areas

* easy coal production

* fast smoke exhaust

We are focusing today on family parrilleros, of sporadic use. Commercial parrilleros, of continuous use, have characteristics and requirements that need to be studied separately.

While we will be studying the parrillero itself, it?s important to consider several elements that can complement it. This could be an adequate exterior space, a paved area where to have a table and chairs, a nearby sink for food preparation; protection from the sun or rain that can be obtained through different plants, pergolas, awnings, metal roofs, concrete slab, etc.

It should be located if possible sheltered from air currents.

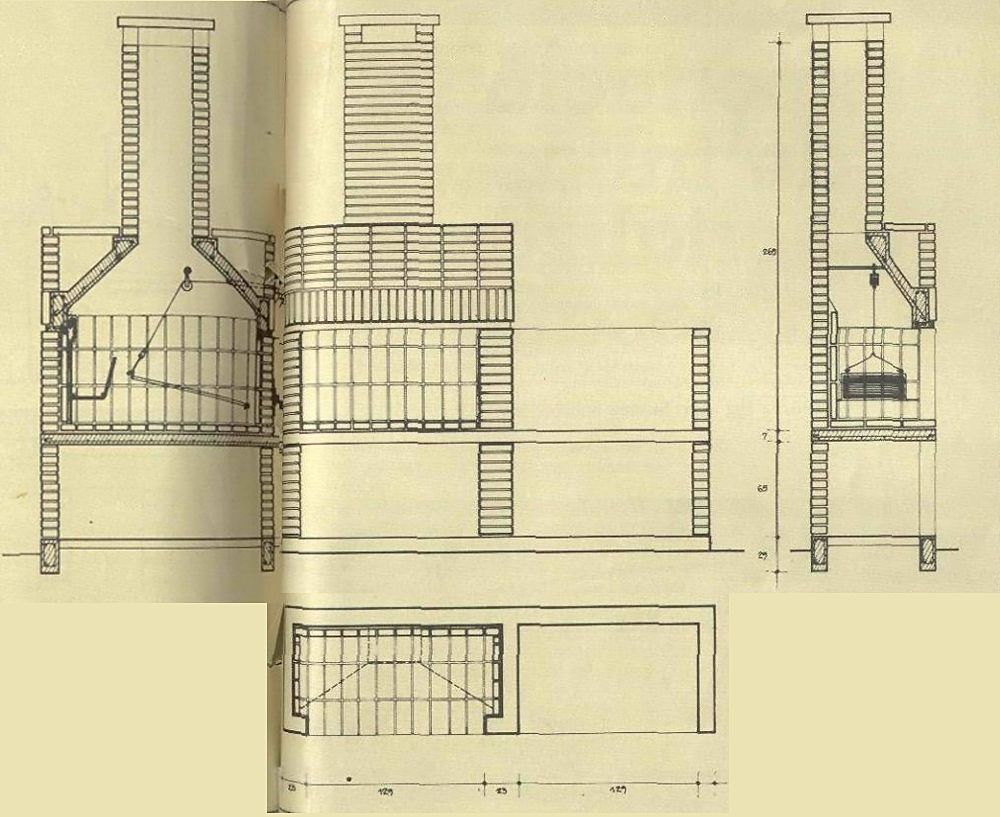

We will analyse the following components of the parrillero:

I. Firewood holder

II. Grill

III. Coal surface

IV. Hood and chimney

I. Firewood holder

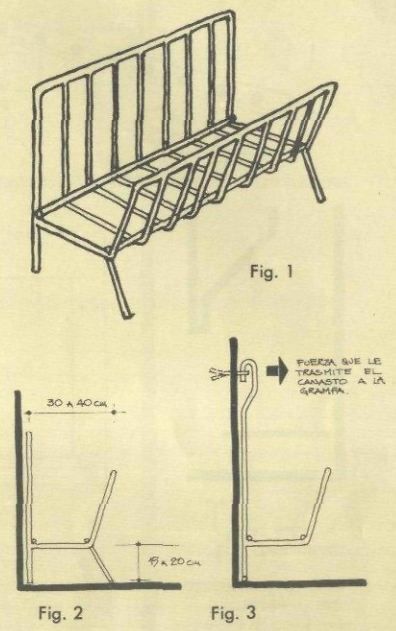

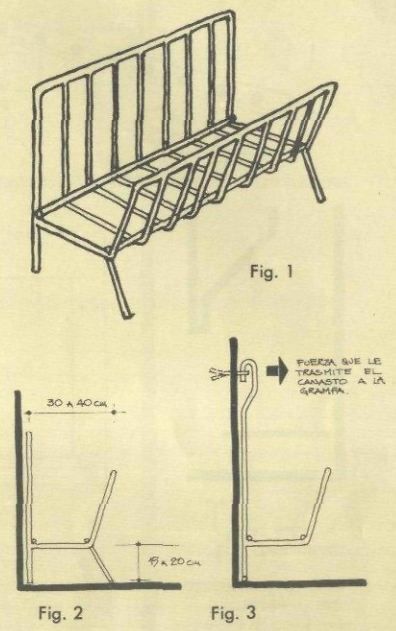

It?s a metallic structure where the firewood is burned. It?s function is to facilitate the production of hot coals.

It?s usually made with iron round stock of diameters varying between 10mm and 19mm joined by welding.

Because it?s exposed to direct fire, it will suffer the process of corrosion. Thus, it is convenient to make it of easy replacement. (Fig. 1)

To have correct combustion and to easily obtain coal, the distance from the base of the holder to the floor surface should be between 15 to 20cm. (Fig. 2)

To have an even easier access to the coals a version of the holder can be used which substitutes the front legs for brackets secured to the wall. The higher this brackets are, the less force they will have to endure.

Since replacing these brackets might be complicated, it?s best if the holder?s weight is supported by the rear legs on the floor. (Fig. 3)

II- Grill

It?s the metallic surface where food is laid to cook.

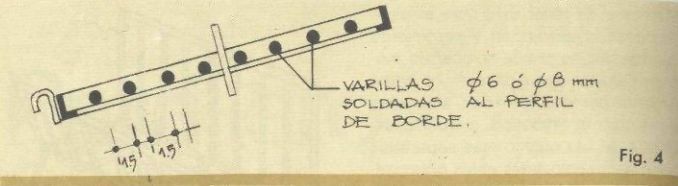

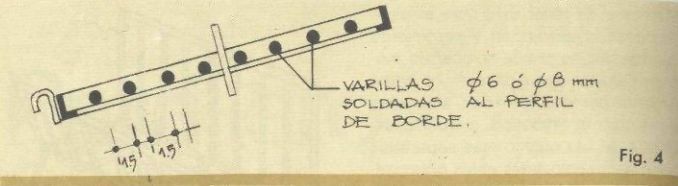

It?s quite common to see it made out of an iron frame (angle iron or thick round stock) to which round stock of 6 to 8mm is welded. (Fig. 4)

Distance between pieces of round stock should be so that they keep food from falling but at the same time letting the heat from the coals through. Said distance can be increased in areas of the grill or a uniform distance can be used through the length of the grill. In this last case the separation between the pieces of round stock shall be of 1.5cm.

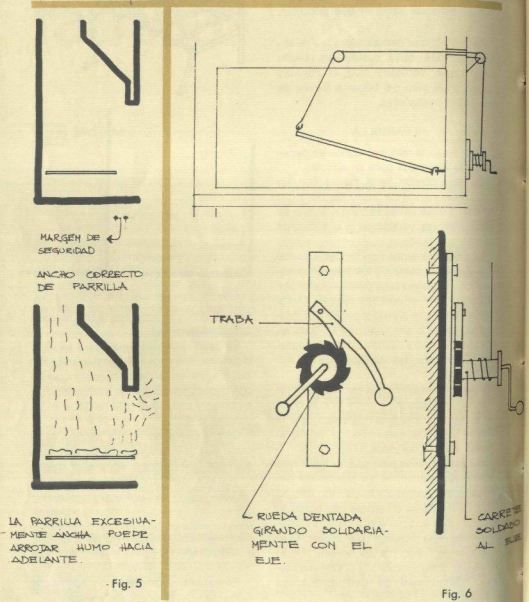

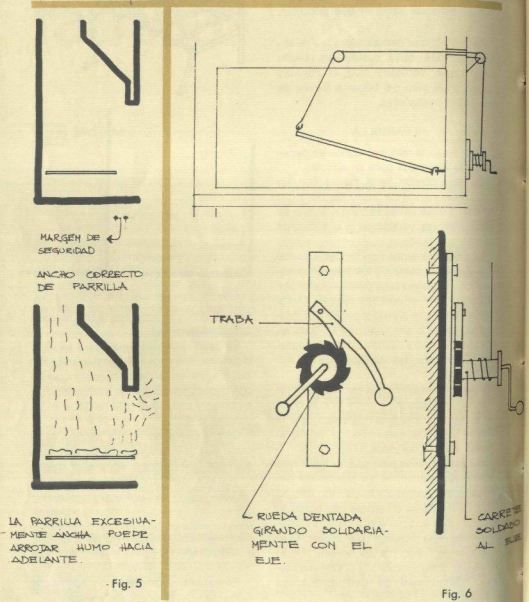

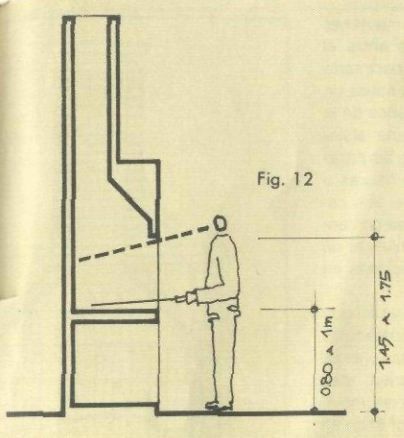

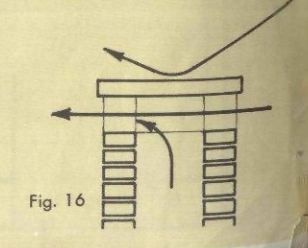

The width of the grill, to keep smoke from coming out of the parrillero opening, shall be limited by it's depth, measured to the inside edge of the lintel. (Fig. 5)

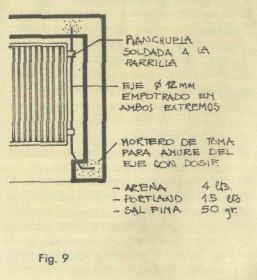

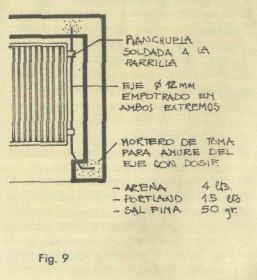

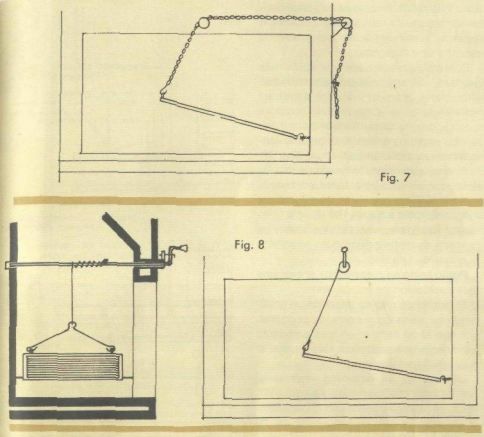

To graduate the amount of heat that reaches the food it?s possible to give the grill some mobility. This is possible through a pivoting axis which allows for varying angles, which will regulate the distances to the burning wood holder and the coals. (Fig. 9)

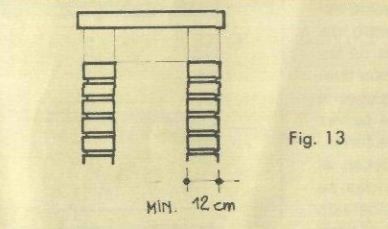

For an even greater mobility several pivots can be installed at different heights. If only one axis is to be used, then it should be located at the second row of bricks (about 12cm from the surface).

...continued

Uruguayan and Argentinian grilling styles differ mostly on the fact that you will never see an asado being made using charcoal in Uruguay, always firewood. Of course, it's mostly a matter of tradition, except for the small amount of smokiness that can be transferred to the meat (yum).

A small note on the use of the word parrillero throughout the document: in uruguayan spanish a grill, as in cooking surface, is a parrilla. A grill, as in the whole structure that holds the cooking surface, hood, etc, is called a parrillero (not so in Argentinean spanish, where the parrillero is the cook using the grill). I couldn't find an equivalent word in english to translate it, so I kept using parrillero throughout.

Images are from a scan of the original document, which can be found in pdf form here (in spanish): parrillerofamiliar.pdf

Here it goes:

Originally published in the 1988 Almanaque Anual del Banco de Seguros del Estado (Uruguay)

By Arq. Diego C. Venturini

The delicious practice of grilling and savoring meat ?on the coals? exists within our people since yore.

Throughout time said practice has been perfected and from the old parrilla criolla laid on the ground, different improvements have been made, looking in them to achieve more comfort and efficiency.

The main objectives, when building a parrillero are:

* firewood economy

* time saving

* comfortable working areas

* easy coal production

* fast smoke exhaust

We are focusing today on family parrilleros, of sporadic use. Commercial parrilleros, of continuous use, have characteristics and requirements that need to be studied separately.

While we will be studying the parrillero itself, it?s important to consider several elements that can complement it. This could be an adequate exterior space, a paved area where to have a table and chairs, a nearby sink for food preparation; protection from the sun or rain that can be obtained through different plants, pergolas, awnings, metal roofs, concrete slab, etc.

It should be located if possible sheltered from air currents.

We will analyse the following components of the parrillero:

I. Firewood holder

II. Grill

III. Coal surface

IV. Hood and chimney

I. Firewood holder

It?s a metallic structure where the firewood is burned. It?s function is to facilitate the production of hot coals.

It?s usually made with iron round stock of diameters varying between 10mm and 19mm joined by welding.

Because it?s exposed to direct fire, it will suffer the process of corrosion. Thus, it is convenient to make it of easy replacement. (Fig. 1)

To have correct combustion and to easily obtain coal, the distance from the base of the holder to the floor surface should be between 15 to 20cm. (Fig. 2)

To have an even easier access to the coals a version of the holder can be used which substitutes the front legs for brackets secured to the wall. The higher this brackets are, the less force they will have to endure.

Since replacing these brackets might be complicated, it?s best if the holder?s weight is supported by the rear legs on the floor. (Fig. 3)

II- Grill

It?s the metallic surface where food is laid to cook.

It?s quite common to see it made out of an iron frame (angle iron or thick round stock) to which round stock of 6 to 8mm is welded. (Fig. 4)

Distance between pieces of round stock should be so that they keep food from falling but at the same time letting the heat from the coals through. Said distance can be increased in areas of the grill or a uniform distance can be used through the length of the grill. In this last case the separation between the pieces of round stock shall be of 1.5cm.

The width of the grill, to keep smoke from coming out of the parrillero opening, shall be limited by it's depth, measured to the inside edge of the lintel. (Fig. 5)

To graduate the amount of heat that reaches the food it?s possible to give the grill some mobility. This is possible through a pivoting axis which allows for varying angles, which will regulate the distances to the burning wood holder and the coals. (Fig. 9)

For an even greater mobility several pivots can be installed at different heights. If only one axis is to be used, then it should be located at the second row of bricks (about 12cm from the surface).

...continued

Comment